Quonset Hut Steel

There were a number of issues that delayed starting on the Quonset hut, including two extra weeks for delivery and I had to travel to Europe for a two week business trip… but eventually all the plans were in place and we had a nice weekend forecast (for late October), so my parents and sister (Bonnie) came down from Canada to help out.

The Video:

You can find the full video here:

This all happened about a month ago… But it takes a while for me to find the time to put these videos and blogs together… At the time, I made a short and quick video and posted it to Facebook. Generally, the facebook posts are much closer to real time and are much much shorter than the bog posts. If you are interested, you can like us on Facebook (click over here in the right hand side è)

This all happened about a month ago… But it takes a while for me to find the time to put these videos and blogs together… At the time, I made a short and quick video and posted it to Facebook. Generally, the facebook posts are much closer to real time and are much much shorter than the bog posts. If you are interested, you can like us on Facebook (click over here in the right hand side è)

This is the short video that I posted on Facebook a month ago…

The Numbers:

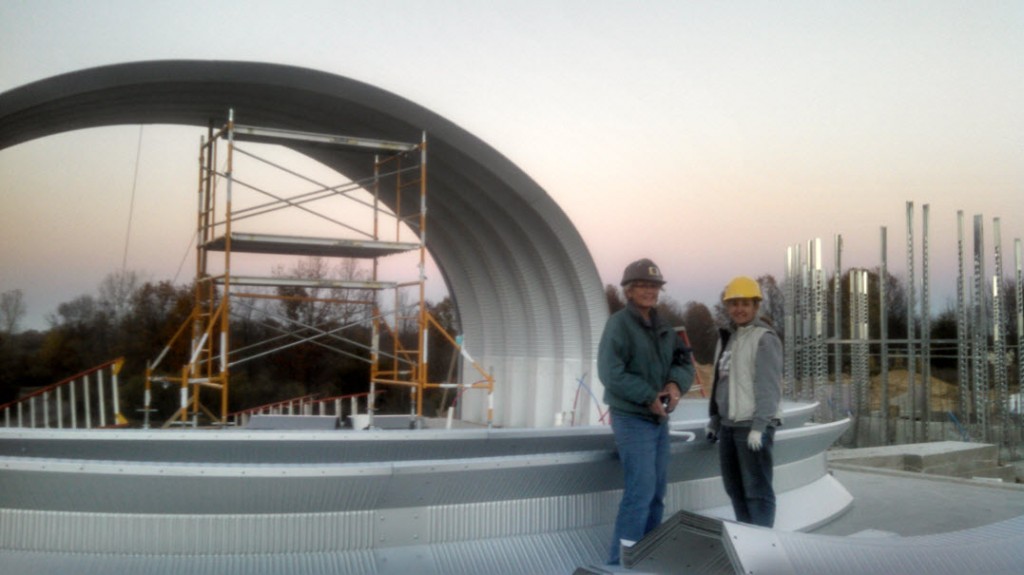

Each arch is made up of 7 pieces of steel bolted together with half inch bolts. Each arch section ends up weighing ~240 lbs. This portion of the building is my garage/workshop and will eventually have 20 arches and be 30 ft wide and ~40 ft long. For now, I have only put up 11 arch sections because I plan to build some forms for casting concrete ribs in the back and then roll them to the front where a crane can lift them up and move them into place.

The garage steel came on 1 pallet weighing about 4800 lbs. It included 2 buckets and 2 boxes containing about ~5000 pairs of nuts and bolts. The cost for the steel/nuts&bolts/engineering/delivery was $7200.

The garage steel came on 1 pallet weighing about 4800 lbs. It included 2 buckets and 2 boxes containing about ~5000 pairs of nuts and bolts. The cost for the steel/nuts&bolts/engineering/delivery was $7200.

To assemble the arches, I used the help of friends and family… No one who helped had ever done anything like it before. The first Saturday, I had my parents and sister to help for nearly 12 hours, pre-dawn to dark. We got up 6 arches, which means it took an average of about 8 man hours per arch. Actually, the second arch took 3 hours and 40 minutes, which is about 14.66 man hours… And the 6th arch took 1.5 hours or 6 man hours. That is a decent learning curve. The second Saturday is harder to calculate because I had different people who came at different times for different numbers of hours. The first arch was done by 3 people and some time was lost giving tours to arriving friends, etc. but we were starting on the second arch by 2 hours and 10 minutes later, which is 6.5 man hours. The 9th arch (the last one that we had a full crew for) took 7 guys only 35 minutes, which is just over 4 man hours.

In total, my friends and family gave me 94 man hours over those two Saturdays. If I had to pay a moderate 20$/hour, that would have cost me $1880 in labor. I never got a quote to get the building professionally assembled, so I am not sure how that compares. However much I saved, I really appreciated the help and I hope they had some fun doing it.

The Mistakes:

- There was that one piece that we didn’t overlap in the right direction… It should be OK in the end because the seam is almost at the top and we plan to cover the structure in concrete anyway.

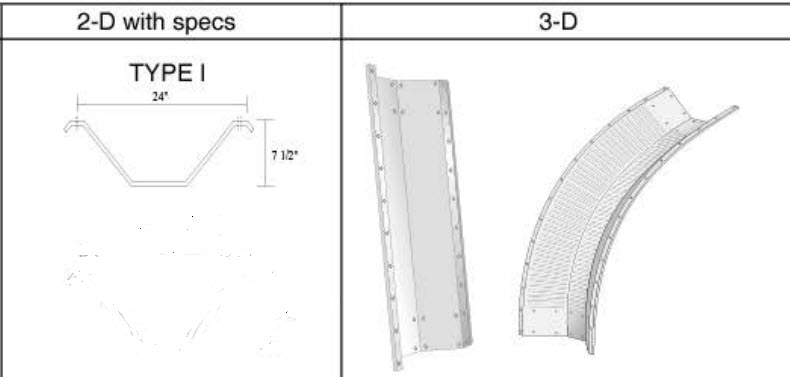

- I was not able to get the width down to 24 inches each for the arches… I was always half an inch over. I don’t think it will affect the strength much and the extra bit was balanced on both sides, so the building is straight. The biggest problem is that the structure is already about 6” longer than it should be. I don’t yet know how I will handle it when I add the remaining arch segments and get to the end of the slab… I don’t think I want to add an extra footing to move the front wall out 8 inches. The other options include not using the last arch, or perhaps cutting the last arch… I won’t really know how big of a mistake that was until the garage is complete.

Actually, I think this drawing from the manual is a little wrong… The text says over and over again that the 24″ should be bolt hole center to bolt hole center…

The Story:

The assembly actually began on Friday. I knew we had a lot of hours ahead of us, so I asked my friend Aaron to come out and help me get 4 ribs together. It took us about an hour to get the first couple together. We timed the second couple and managed to get down to 17 minutes for each of those.

We arrived before dawn and were prepared to raise the first arch soon after sunrise. The arches went up pretty easy, for a 240lb arch of 20 gage steel. The biggest issue was really how flexible they were…

The first one had nothing to lean it against, so we braced it with wood and rope and then hurried to get the second one up to stiffen the assembly. The second arch was very difficult. I thought it was going to collapse at one point and I was seriously questioning my plan to erect this structure without any professional help.

However, as we bolted the two arches together, things started firming up. This was good because the wind started to pick up. You can see things start to move and shake in the video. I spent a lot of time stressing about the width of the arches, but it was really the wind that made me push on to get a few more arches up to increase the stiffness of the structure. The instructions said to assemble 4 sections and then tweak the building, so we moved ahead.

The 3rd and 4th sections went up pretty easily. We had a pretty good rhythm for bolting things together and it helped that the sun was out and things were warming up nicely. We now had almost a ton of steel up and the wind was not flexing it as much.

After the 4th arch, my father and I were fighting with the steel to try and get the width down to 24 inches… We just could not compress it that far. The depth was correct, and that made no sense to me.

Since I was too distracted to provide any guidance, the ladies took the initiative and started assembling the 5th arch on their own. Unfortunately, they assumed all the steel pieces were the same… which would have been right for a true Quonset, but this was an “S-type” made up of two different radius pieces. It was clearly curving too much and Bonnie realized something was wrong. She interrupted my stressing and said, “Hey are there two different radius pieces here?” Oops, I felt bad for letting them waste their time. I took a moment to explain the two different curvatures and how the pieces went together and then they got back to work.

I eventually accepted the slightly greater than 24 inch width and started drilling holes and bolting down the arches. Perhaps this was a big mistake, but I couldn’t see any other way forward.

The view from the top was nice though…

The 5th arch went up very easily and the ladies (now expert) began to assemble the 6th arch while the men bolted the 5th to the 4th. Sherri and the boys arrived just as we were getting ready to raise the 6th arch. It had been tough for me to manage all three ropes during the pull, so I was glad to have Sherri up there to help. After the 6th, it was clear that the day was ending and we wouldn’t necessarily have time to get another arch fully in place and properly secured before dark… We decided not to try and raise any more ribs that day. Instead, we just prepped for the next Saturday.

My family went home to Canada and I spent the next week trying to get enough local friends together to help me put up a few more arches before winter really set in… Many of my friends had prior commitments or were working, etc. Some could come for earlier hours, some could come later, Some could only come on Sunday instead of Saturday, etc. I was mostly concerned about not having enough guys there at one time to actually pull up the ribs. However, by Thursday, I did get enough to sign up for a fun workday in the freezing cold.

On Saturday morning, Aaron and Don showed up first. Since we didn’t have enough people to pull a full arch into place, we decided to try the “piece by piece” method. It actually worked pretty well, although it was a bit slower than the other method and we did make one overlap mistake (probably because we were rushing).

Then more friends arrived. Carl and his son Kent came with Doug, so we had an instant crew. A while later, my brother-in-law, John, arrived. Getting the arches into position with that many guys was pretty easy and then we had several pairs working on bolting things all together… The biggest bottle neck was waiting for me to anchor the arches to the concrete at the end. My previous approach had been to work bolting the ribs together, and then work on anchoring the previous arch (we kept the current arch loose so the next one could be fit over it easier). However, with so many guys bolting the arches together, it made much more sense for me to start anchoring the previous rib as soon as the new rib was up, but I still couldn’t finish before the guys got the rest of the bolts in place. We got pretty fast by the end of the day.

Next, I will need to grout the trench. The building is attached to the ground, but doesn’t have real strength until the feet are fixed in place so they can’t lean in or out.

Response to Erecting the quonset hut steel

gower says:

Where did you find the adaptor plates? In order to attach the bottom of the arches to the concrete.

Simon says:

The little L brackets that I used came in the kit from steelmaster buildings. It is only an option if you put the Keyway into the concrete to hold the lateral loads. I only had to buy the sleeve anchors to bolt them to the concrete. They also have much stronger (and much more expensive) solutions if you don’t put in the keyway. One is called the “Industrial Base Connector”.

Nina says:

Hello Simon, thank you for posting. I am in the middle of building an S style too. Mine is 17 high in the middle and 30 wide. I am using the c-channel to attach the building to the foundation. Everything was going great (well it all looked plumb) until we got to the 9th arch (of 24). Now the top center is bowing out and the wall panels don’t want to line up. You mentioned in your post that you couldn’t get the arches to remain 24 inches. I was wondering how things turned out in the end. Did your building bow in the middle? Did you use the metal arch bracing straps? Would love to hear your thoughts.

Thank you.

Simon says:

I had to leave the front half open because I was lifting things off the pad with a crane, but I am 12 sections in (24 ft) and already 8 inches over length. The slab is my limiting factor, so when I get to within the wall thickness of the end, I will need to trim my last arch section. My vertical portion (the S type has a 4 ft vertical portion) still seems nice and vertical and the rest of the shape “looks” right.

We did put up a vertical post in the middle at the correct height, so maybe that kept things from sagging before we tightened all the nuts? We did not use the pieces of angle iron that they sent with the building. They had pre-drilled holes and (by the time we tried) we couldn’t quite make things fit.

Have you talked to your buildings manufacturer to see what they have to say?

Nina says:

Simon, I did talk to steelmaster, the manufacturer, and they told me to loosen the bolts for the last three arches. We loosened the bolts, used a deadman support to lift the last 3 arches in the middle of the arch and things started to line up. It was wasn’t easy getting the deadman in place and lifting the center but it made a huge difference. The building is now up and is straight and plumb. Definitely not as easy as I was lead to believe and so thankful it is finished.

Mike Teese says:

I am planning on buying a Quonset hut to build a home. Really curious what other people have paid for their building. I am planning on purchasing an S-model about 30’x40’x18′. The problem is the sales people are like used car salesmen and it is difficult to determine what a fair price is. I would love to know what other people have paid for theirs which would help me in my negotiations. Looking at Steelmaster.

Thanks

Mike

Simon says:

Mine was a S-30x40x14. I paid $7000 US delivered. I did not get the end walls or the ground kit, door hardware, etc. Those extra little bits could double the price.

Errol D. Severe says:

Contact Future Buildings in Ontario CA. They make a great product without the “run-around” of some of the other companies. We are in the process of erecting a 55’X40′ S-type. (55 Wide)

Jamie says:

What did you mean by the S type having 2 different radius pieces? I’m putting up my 40×80 and we’ve run into 2 different lengths of panels and can’t seem to find anywhere online where the longer pieces go and where the shorter ones go. Any help is appreciated.

Simon says:

Different lengths are so you put them in “running bond” pattern without seams lining up. So put the small one on the right for the first arch, then in the middle for the second, then on the left for the third… Actually, any pattern is fine as long as the seams won’t line up. The different radius is something else… The “shoulders” of the building have a tighter radius than the top. The two shoulders are the same length, just with more curvature than the other pieces in each arch.

pipeman says:

Thanks Simon for sharing this incredible build. I’m considering purchasing a Quonset Hut myself and have a couple of questions. You say in your video that your steel is 16 gauge, but state on your website it’s 20 gauge. Which is correct? And secondly, knowing that you were going to rebar and shotcrete the building and then bury it, did you choose the thinnest gauge steel because it’s simply a form? One would think you would have chosen a thicker gauge, but apparently the opposite is true. Is this correct?

Simon says:

I ended up going with the thinner (the standard) steel quonset. 20 gauge was correct. They recommended the thicker quonset hut for “burial”, but they meant direct burial. Since I planned to use the quonset as just fancy formwork, it didn’t need to be nearly as strong and the 20 gauge was plenty. Factor in that the 16 gauge was going to be about double the cost and quite a bit more effort to lift into place, and I am glad I went thinner.

Darrell Flannery says:

This is a great bit of knowledge in the assembly. I’m preparing to build a 30 x 80 myself and was wondering how wide you made your slab. My kit didn’t come with anything resembling a proper foundation design. I have calculated a 3 inch width on each side making it a 30′ 6″ width. I’m using angle iron and j-bolt connections to the slab then bolting the arches to the angle. I figure with the slots in the angle I can square up the structure using ratchet straps and the center post support like you used in the video to remove some of the load from the sides of the arches. Anyway… that was an awesome video. I might be inspired to document my project for others as well.

Simon says:

The trench its self was at least 7 inches wide and then I wanted some thickenss beyond that. I don’t think 3 inches would be enough. Perhaps call the manufacturer. If you are bolting down to the slab, then I guess you wouldn’t need the outer edge to be holding it in, so it could be narrower.